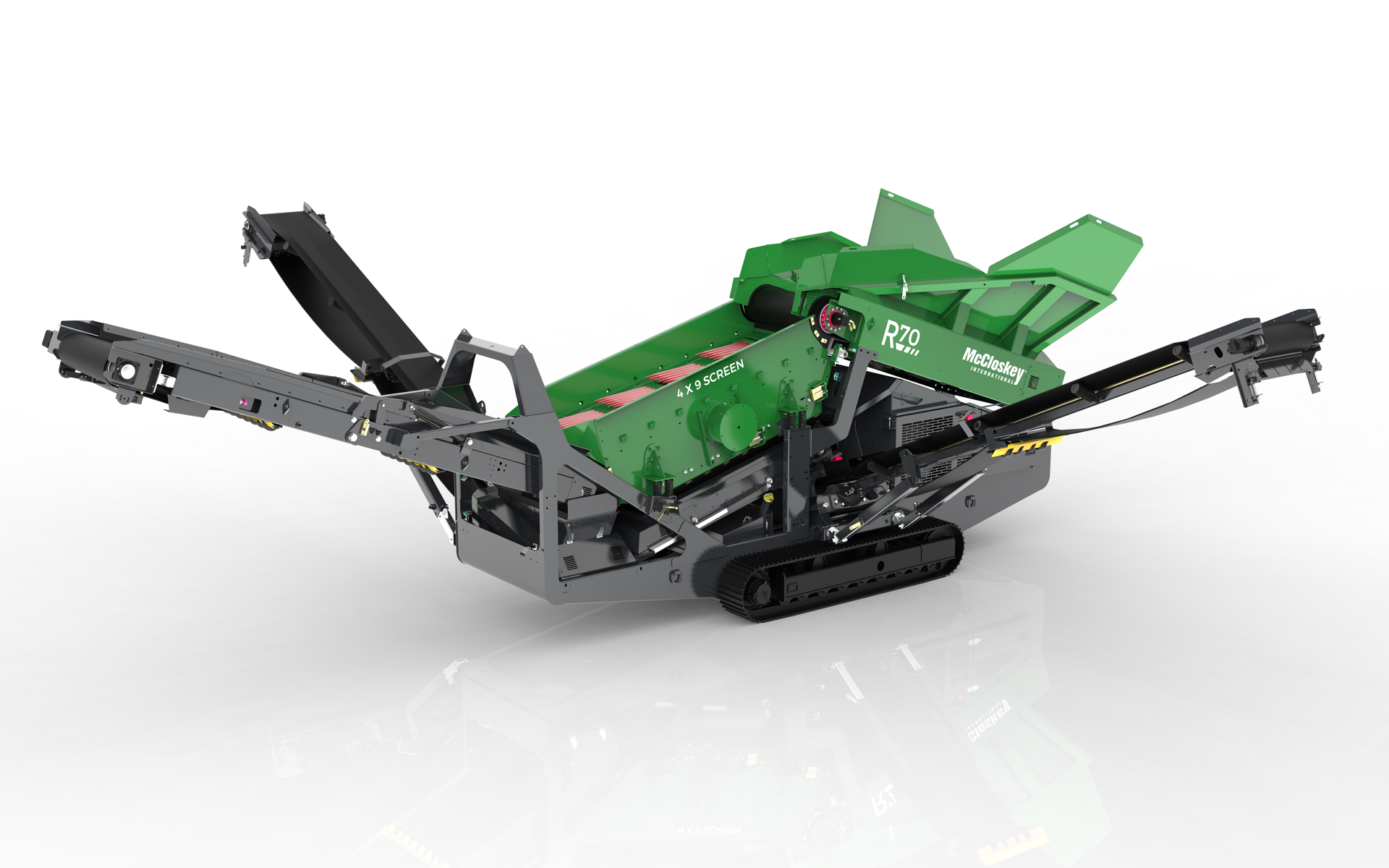

McCloskey R70 Scalper | Reclaimer

- Construction and demolition waste screening

- Site remediation and topsoil separation

- Aggregate pre-screening

- Smaller quarry or recycling operations

Machine Weight

16,000KG Appox

Machine Weight

16,000KG Appox  Capacity

3OO T/H*

Capacity

3OO T/H*  Engine Size

130HP

Engine Size

130HP Screenbox

9' x 4'

Screenbox

9' x 4'  Apron Feeder available

YES

Apron Feeder available

YES

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.