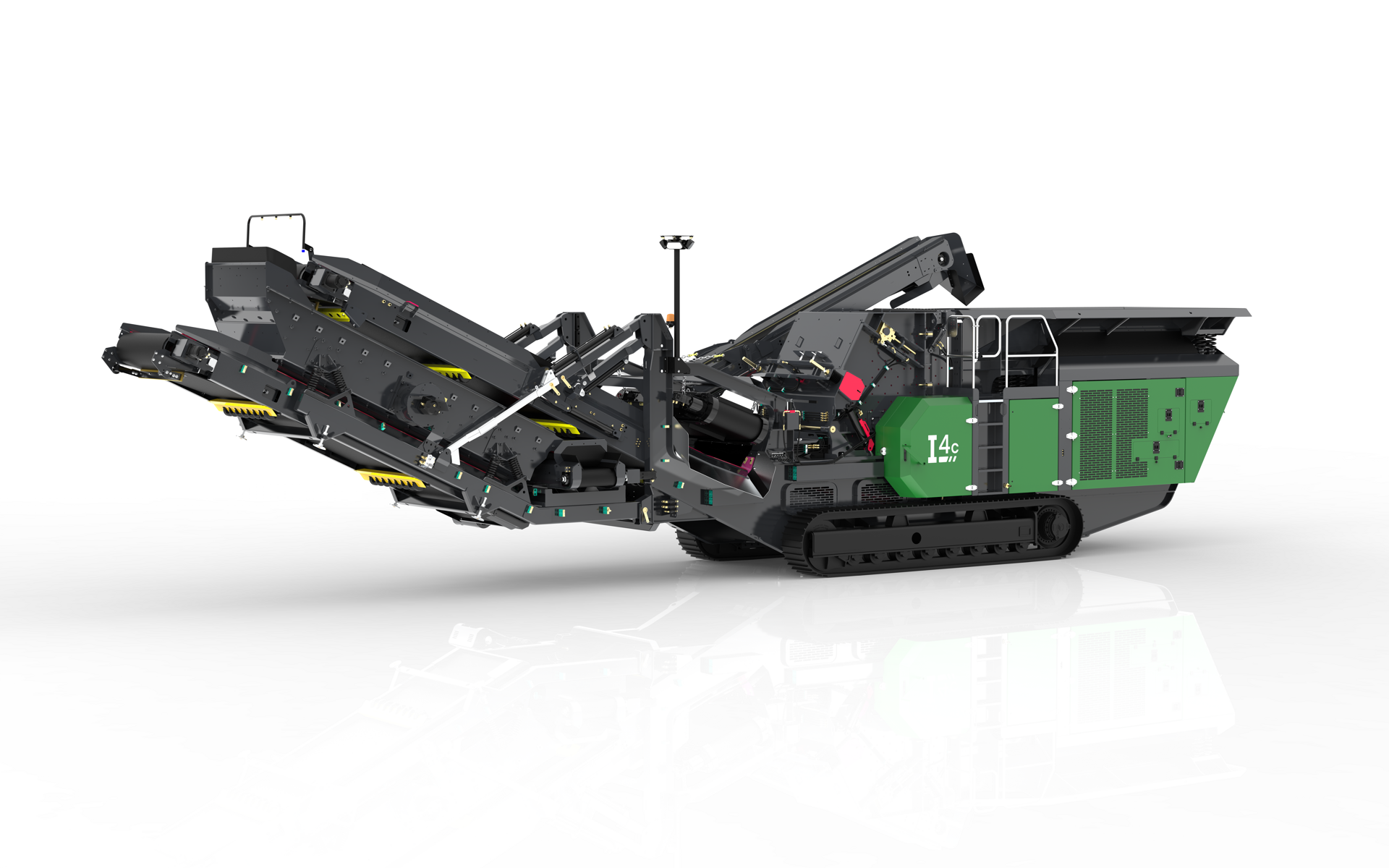

McCloskey I4CR Impact Crusher

Ideal Applications

-

-

Heavy-duty demolition and concrete recycling

-

-

High-volume asphalt processing

-

Secondary and tertiary aggregate crushing

-

Sites requiring recirculating systems within limited space

Whether on a remote site or an urban development zone, the I4CR provides big-crusher performance in a smart, transport-friendly design.

Why Choose the McCloskey I4CR?

If you're looking for a machine that blends power, precision, and flexibility, the McCloskey I4CR delivers. It’s designed for high-performance operators who need a compact, mobile impact crusher that performs like a heavyweight — without the logistics of one.

Engine HP

375 Hp

Engine HP

375 Hp Weight

40,080kg

Weight

40,080kg Rotor width

1050mm x 1125mm

Rotor width

1050mm x 1125mm Slewing recirc conveyor

YES

Slewing recirc conveyor

YES  Post screen

12'x5'

Post screen

12'x5'

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.