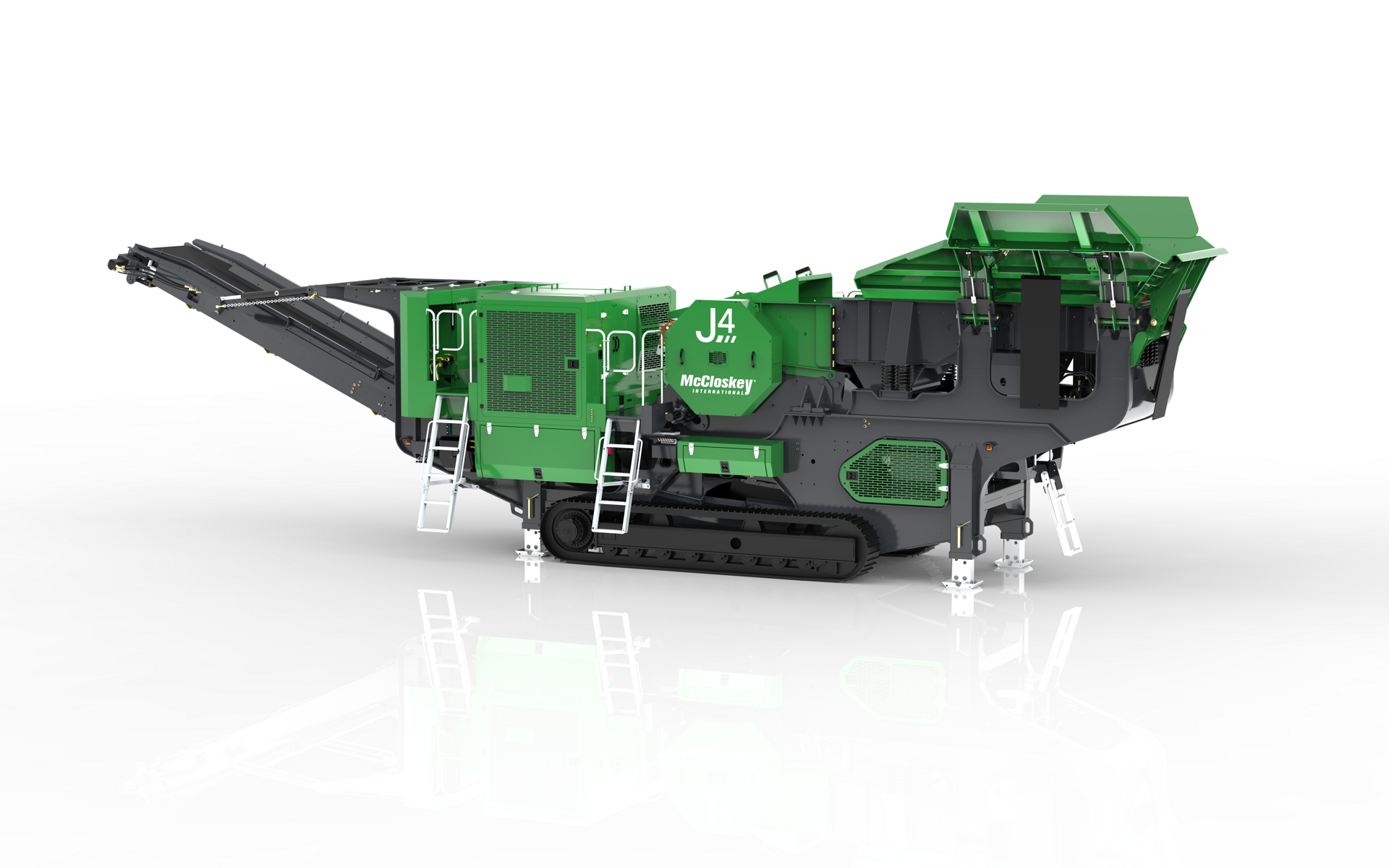

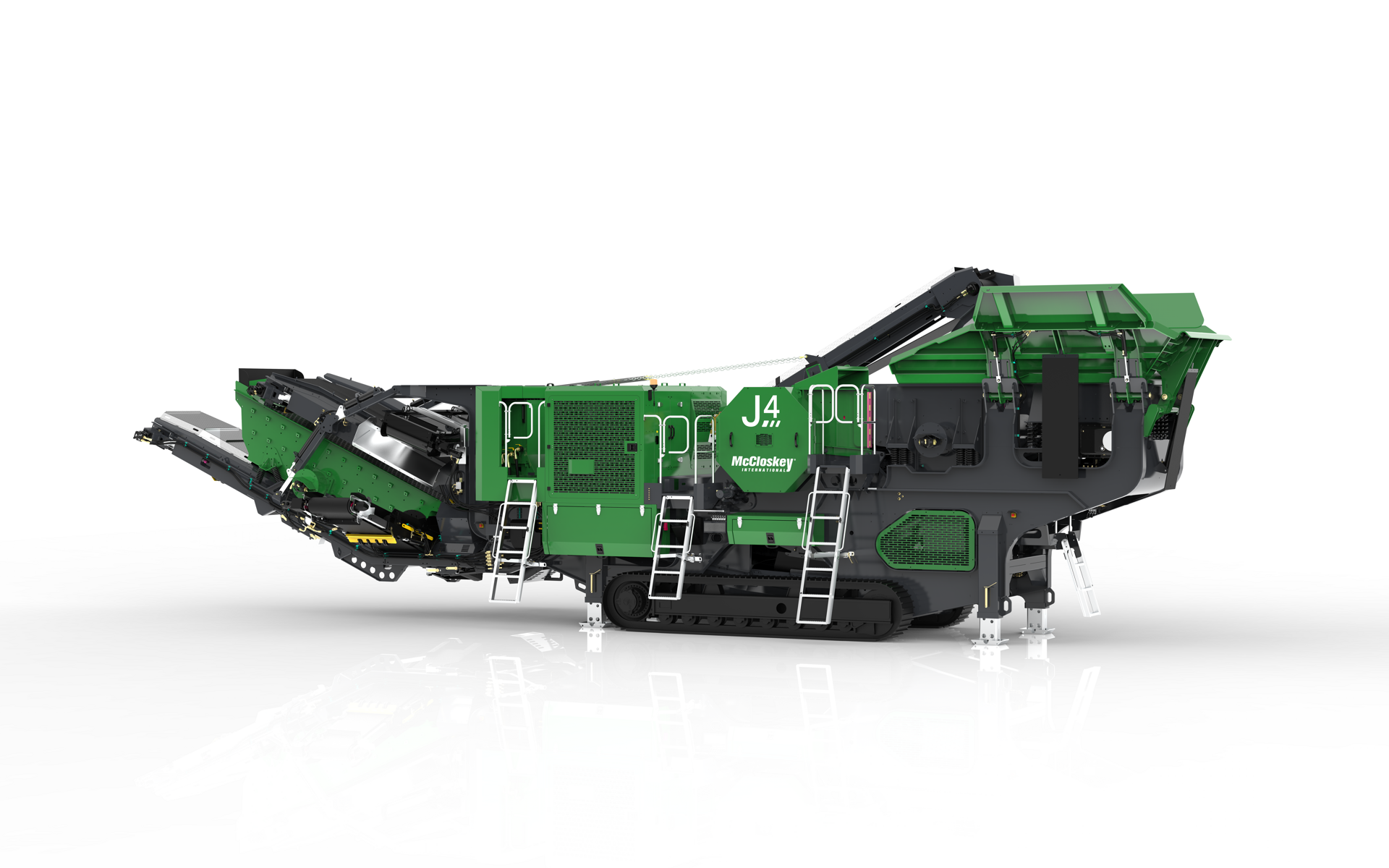

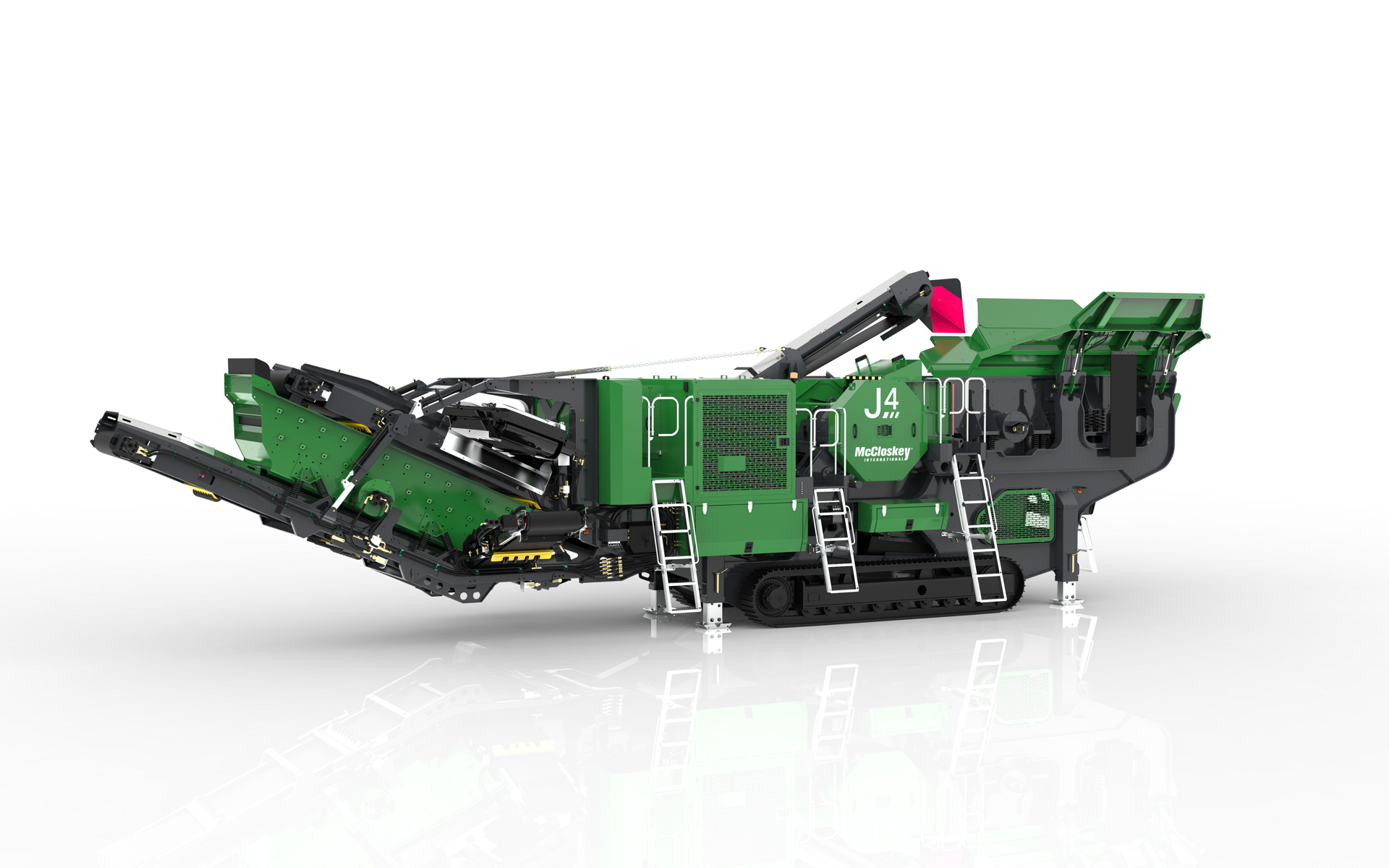

McCloskey J4 Jaw Crusher

With an oversized 1060mm x 700mm jaw chamber, the J4 is capable of handling large feed sizes while maintaining excellent reduction ratios. Its heavy-duty design, paired with advanced hydraulics and a robust 375hp engine, ensures consistent throughput and reliable operation under load.

The J4’s tracked mobility and compact transport dimensions make it easier to relocate across sites. Optional features such as a pre-screening unit, extended main conveyor, and recirculating system offer greater control over product sizing and throughput efficiency.

Performance and Applications

Built for high-output operations, the McCloskey J4 is ideal for:

-

Large-scale aggregate production

-

Hard rock quarry applications

-

Demolition waste processing

-

Road base and infrastructure projects

With a production capacity exceeding 400 TPH (varies by material), the J4 can confidently handle demanding jobs while keeping operating costs in check.

Jaw Chamber

1060mm x 700mm

Jaw Chamber

1060mm x 700mm Weight

51,280kg c/w Dirt Belt and Magnet

Weight

51,280kg c/w Dirt Belt and Magnet  Engine Size

CAT 9.3

Engine Size

CAT 9.3 Independent Pre Screen

Yes

Independent Pre Screen

Yes Hydraulic Drop down conveyor

Yes

Hydraulic Drop down conveyor

Yes

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.