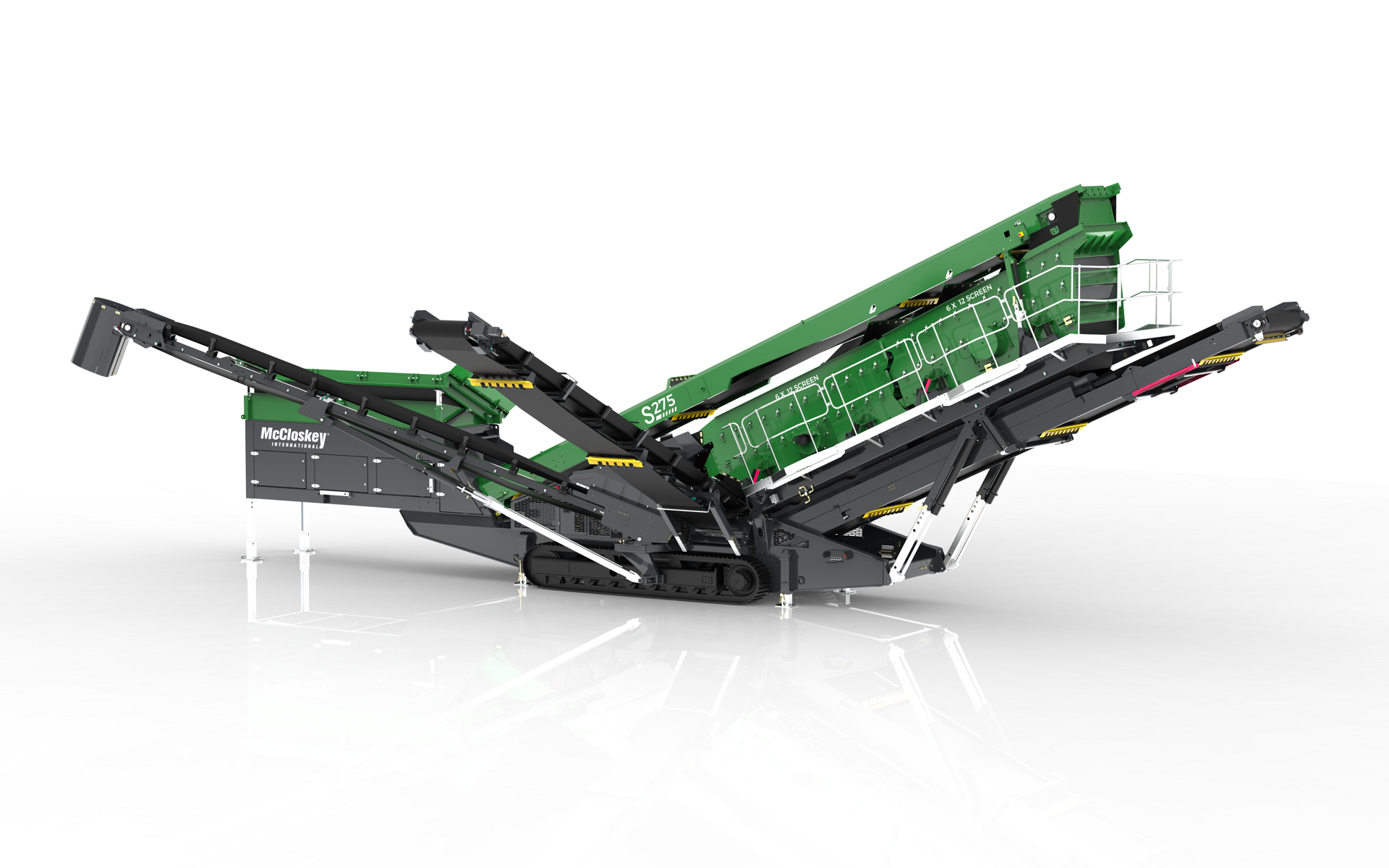

McCloskey S275 Incline Screen

Applications and Performance

Ideal for:

- Quarry and high-volume aggregate screening

- Multi-grade sand, gravel, and crushed rock

- Recycling of concrete, asphalt, and C&D waste

- Soil, compost, and mulch production

- Contractors requiring maximum flexibility in material sizing

With its high energy design and massive screening surface, the S275 consistently delivers clean, spec-grade material — even at high volumes and in challenging conditions.

Why Choose the McCloskey S275?

For operators needing maximum productivity, multi-product flexibility, and industrial-grade durability, the McCloskey S275 is the ultimate mobile screening solution. Whether working standalone or as part of a crushing train, this triple-deck screener delivers top performance where precision and throughput matter most.

Output

800TPH

Output

800TPH Engine Size

CAT C7.1 225Hp

Engine Size

CAT C7.1 225Hp Screenbox

24' x 6'

Screenbox

24' x 6' Machine Weight

42,430KG Approx

Machine Weight

42,430KG Approx

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.