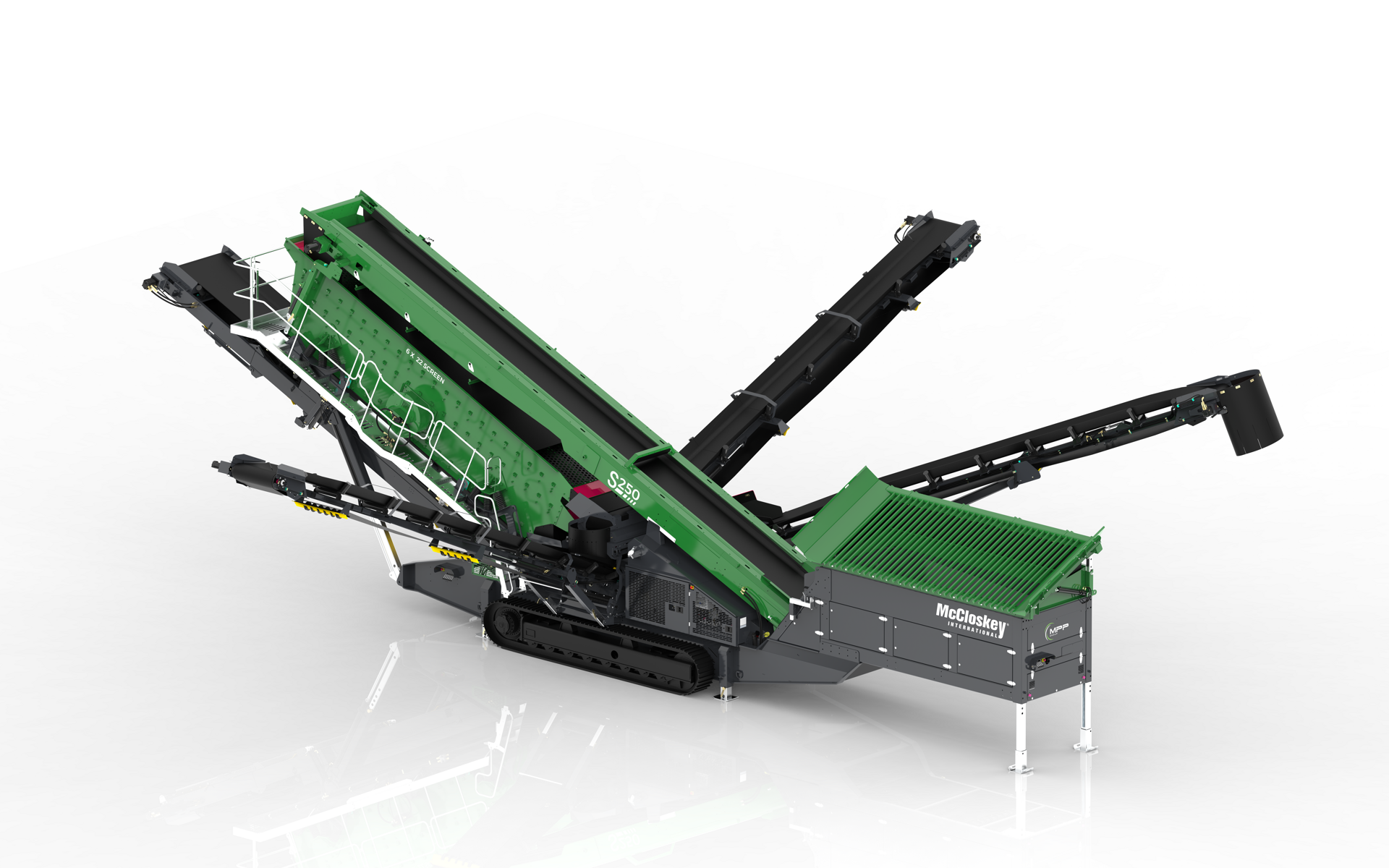

McCloskey S250 Incline Screen

Applications and Performance

Perfect for:

- High-volume aggregate and quarry screening

- Sand, gravel, and crushed stone processing

- Soil, compost, and mulch operations

- Heavy construction and infrastructure material separation

- Multi-size product separation with triple-deck setups

The S250 excels in maximizing throughput while maintaining exceptional precision across a broad range of materials.

Why Choose the McCloskey S250?

For operators who require the biggest and best in mobile screening, the McCloskey S250 delivers. With its unrivaled screening area, massive capacity, and configurable options, it’s the ultimate tool for serious production operations that demand both quantity and quality.

Capacity

Up tp 800 T/H*

Capacity

Up tp 800 T/H* Engine

CAT 225hp

Engine

CAT 225hp Screenbox

22' x 6'

Screenbox

22' x 6' Machine weight

38,000KG Approx

Machine weight

38,000KG Approx 3 deck

optional

3 deck

optional

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.