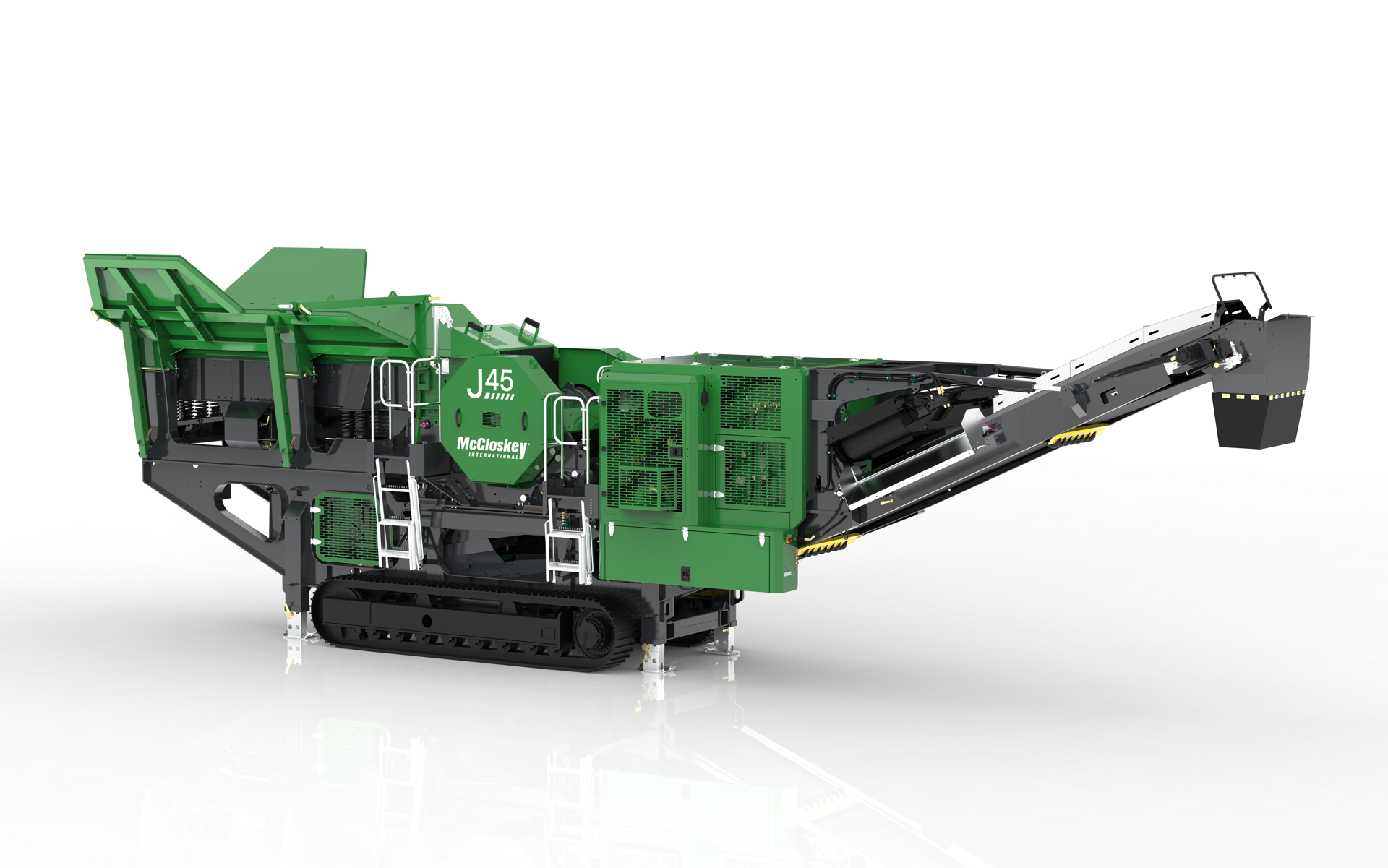

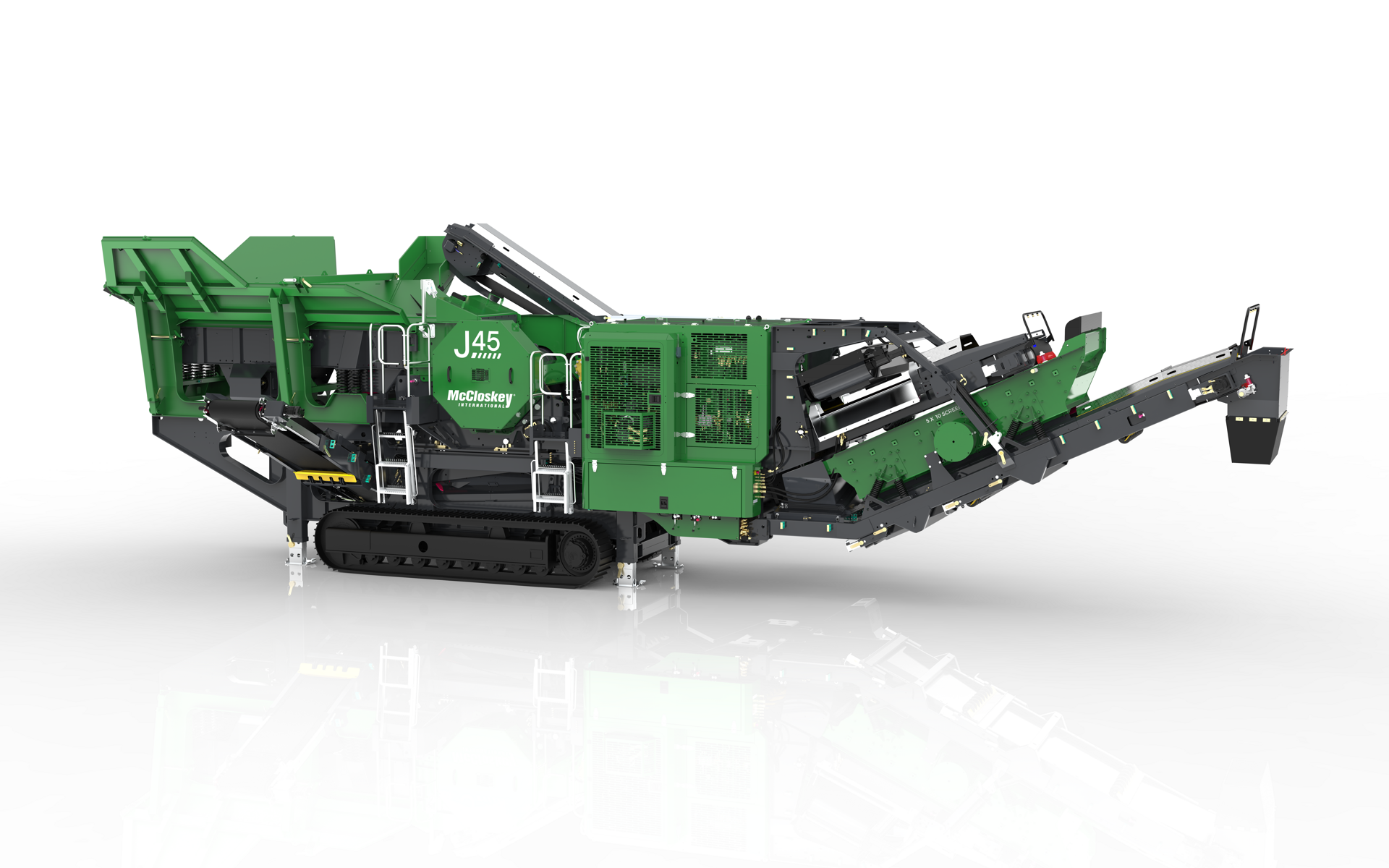

McCloskey J45 Jaw Crusher

Applications and Performance

Designed for maximum uptime and output, the J45 is ideal for:

-

Quarry operations and large-scale aggregates

-

Infrastructure and road construction

-

Concrete recycling and hard rock crushing

-

High-volume mobile crushing setups

Why Choose the McCloskey J45?

If your operation demands heavy-duty productivity with consistent performance, the McCloskey J45 is built to deliver. Combining a large jaw, intelligent material flow design, and transport-friendly frame, it offers the perfect mix of power and versatility for demanding sites across New Zealand.

Machine Weight

43,900KG

Machine Weight

43,900KG Jaw Chamber

1140mm x 680mm

Jaw Chamber

1140mm x 680mm Engine Size

C9 / C9.3 Cat Engine

Engine Size

C9 / C9.3 Cat Engine Pre Screen

YES

Pre Screen

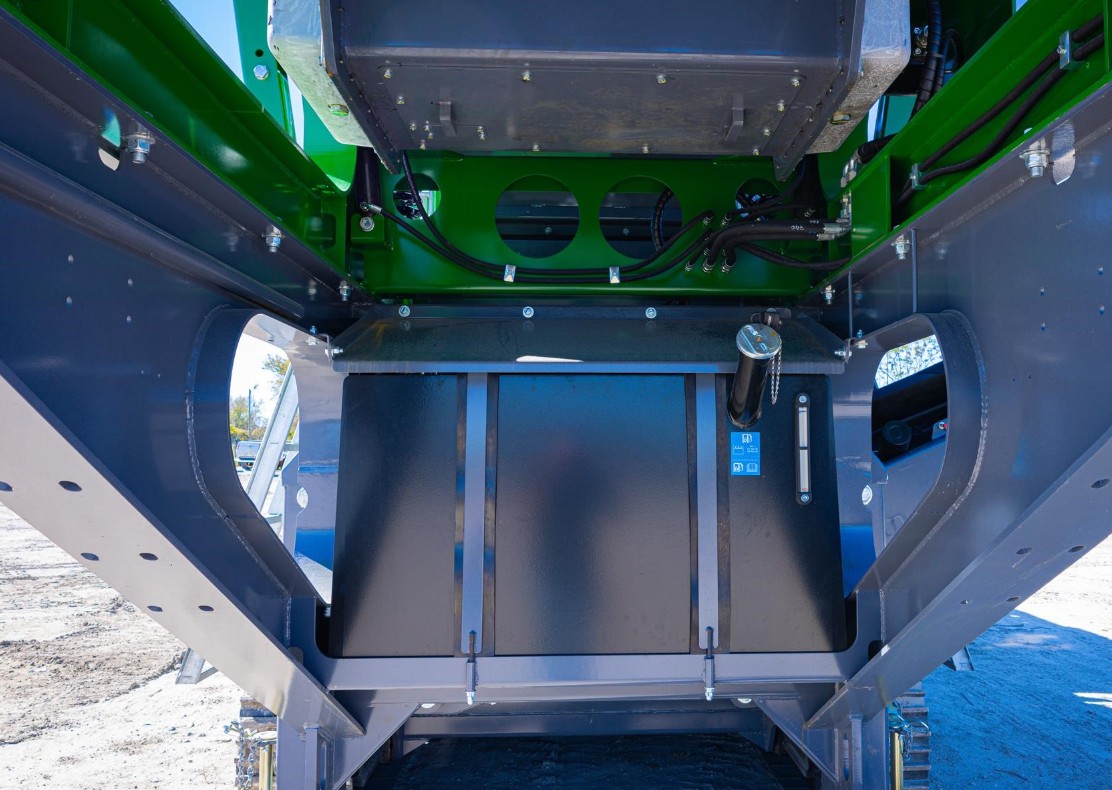

YES Hyd Drop down conveyor

YES

Hyd Drop down conveyor

YES

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.