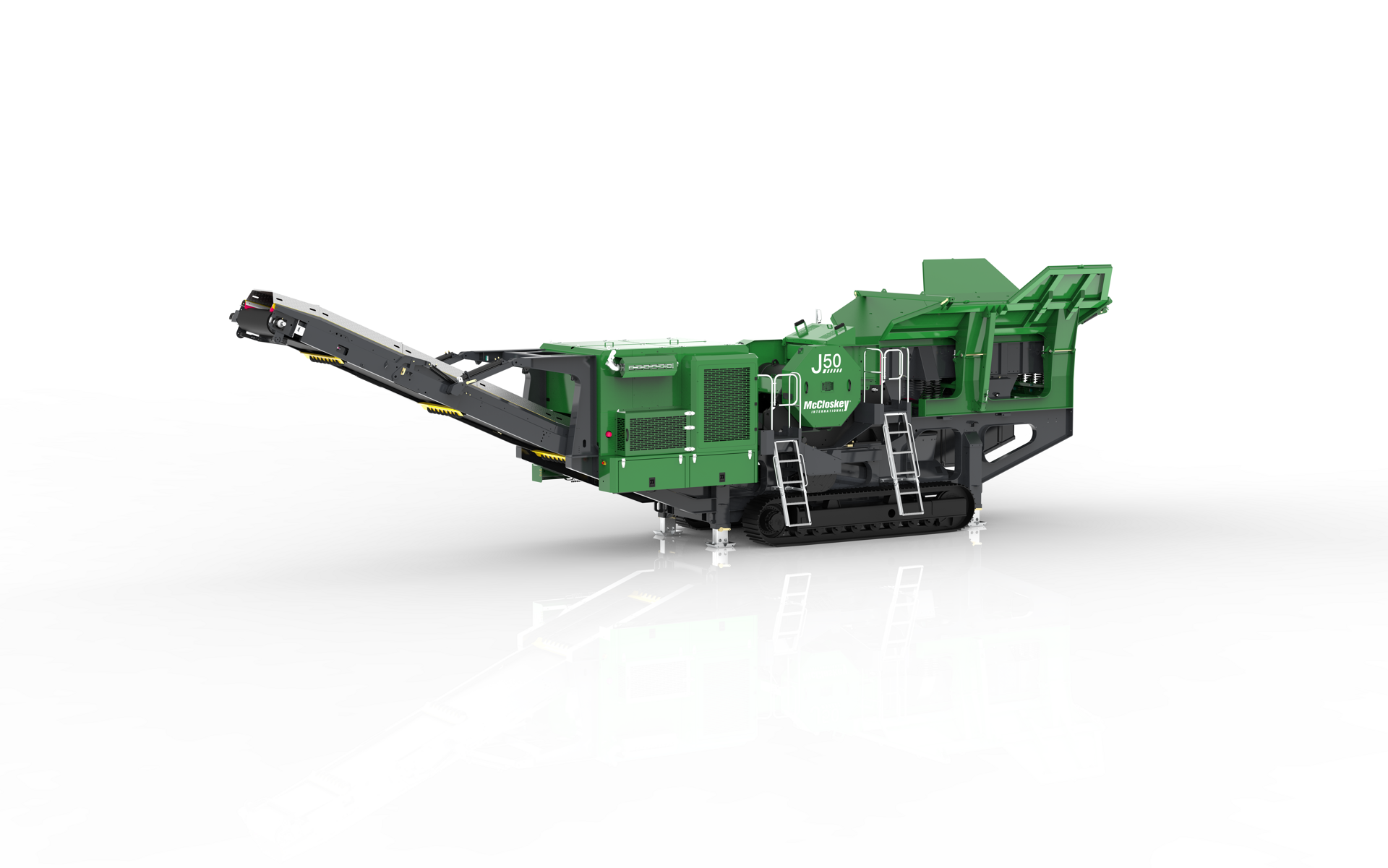

McCloskey J50 Jaw Crusher

Applications and Benefits

Whether you’re processing hard rock, recycled concrete, or demolition material, the J50 offers exceptional capacity and versatility. It's ideal for:

-

Quarry operations and bulk aggregate production

-

Large-scale infrastructure or earthworks projects

-

High-volume mobile crushing in remote environments

-

Operators requiring fast setup and mobility without sacrificing output

Why Choose the McCloskey J50?

If you’re looking for raw power combined with intelligent design, the McCloskey J50 delivers. With its class-leading 50” jaw, high engine output, and mobility, it’s the preferred choice for operators seeking performance without compromise. Rugged, reliable, and ready for any challenge — the J50 is built for serious crushing.

Machine Weight

58,700KG Approx

Machine Weight

58,700KG Approx Chamber dims

1270mm x 730mm

Chamber dims

1270mm x 730mm Engine

CAT C9

Engine

CAT C9 Optional Independent Pre Screen

Yes

Optional Independent Pre Screen

Yes

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.