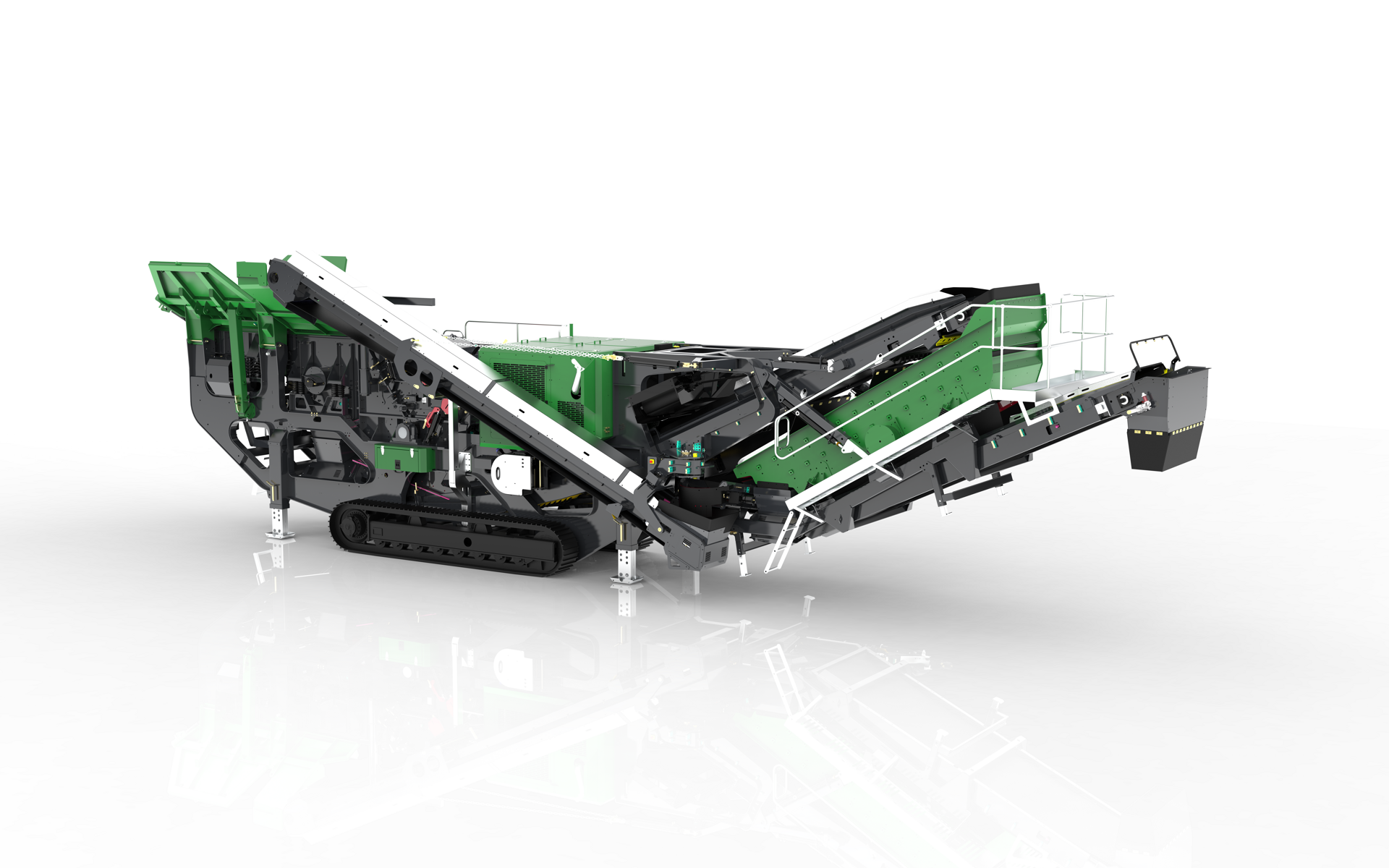

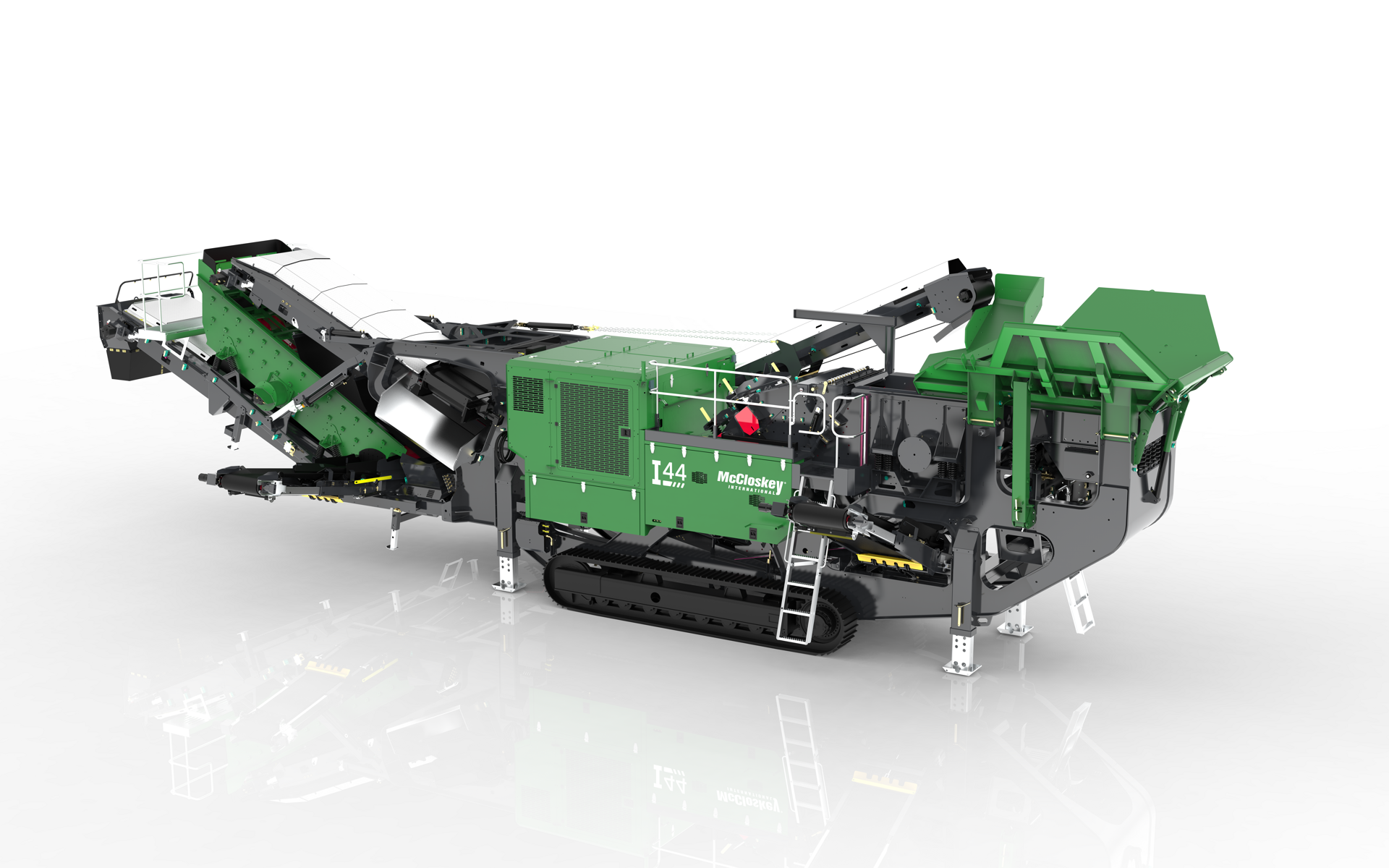

McCloskey I44R Impact Crusher

Applications and Performance

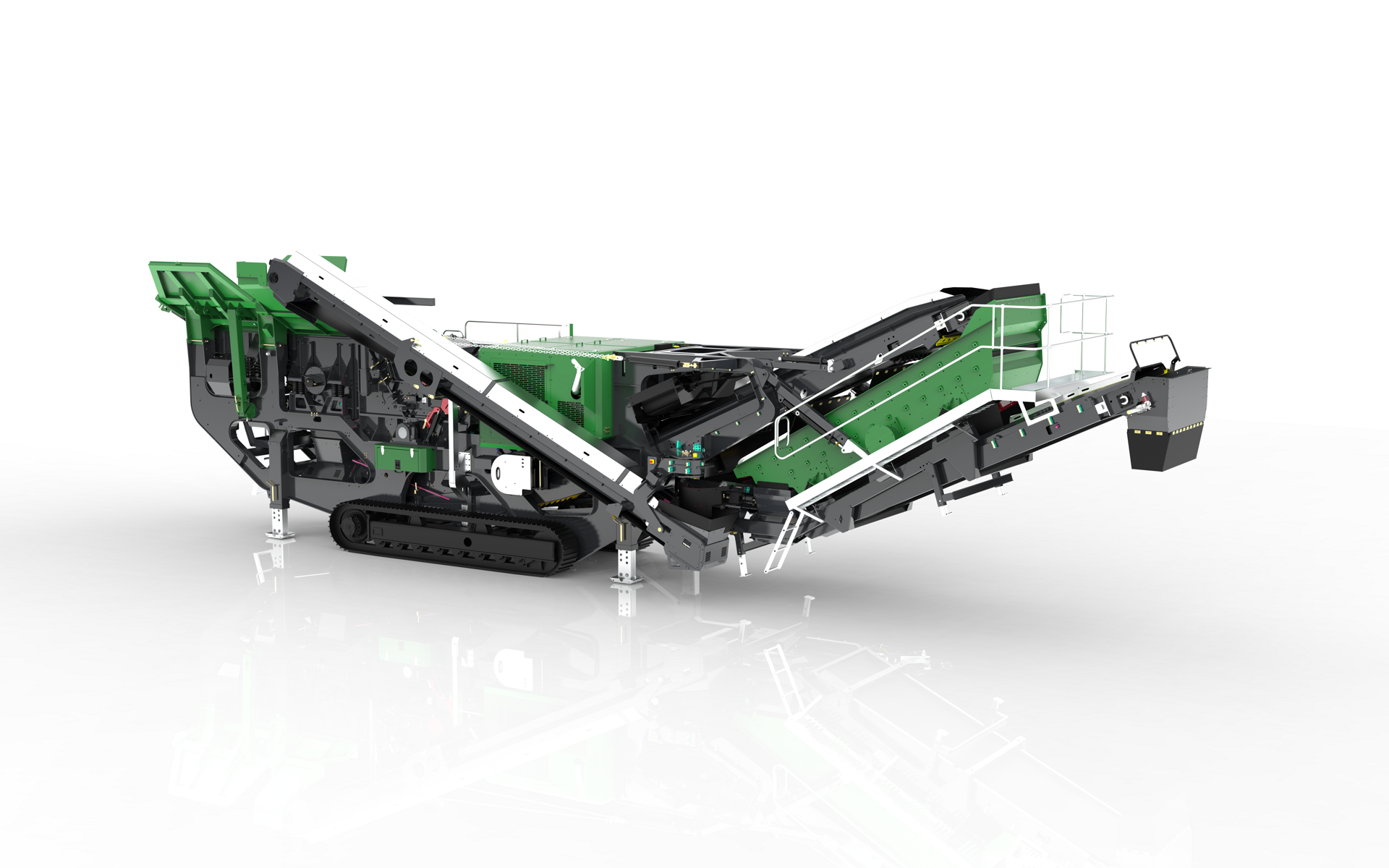

Perfectly suited for:

-

Quarry and aggregate production

-

Concrete and asphalt recycling

-

Infrastructure and road building

-

Contractors needing a crusher-screen combo in one mobile unit

The I44R’s built-in screening system reduces the need for secondary equipment, saving space, time, and transport costs while increasing output efficiency.

Why Choose the McCloskey I44R?

With its robust design, integrated screening circuit, and ability to crush and screen in a single pass, the McCloskey I44R is the go-to impact crusher for high-volume applications. It’s ideal for operators who demand power, precision, and a clean final product — without compromise.

Weight

53,400kg

Weight

53,400kg Max Feed Size

700mm

Max Feed Size

700mm Engine Size

CAT C9 350hp

Engine Size

CAT C9 350hp Impact Rotor

1050mm x 1125mm

Impact Rotor

1050mm x 1125mm

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.