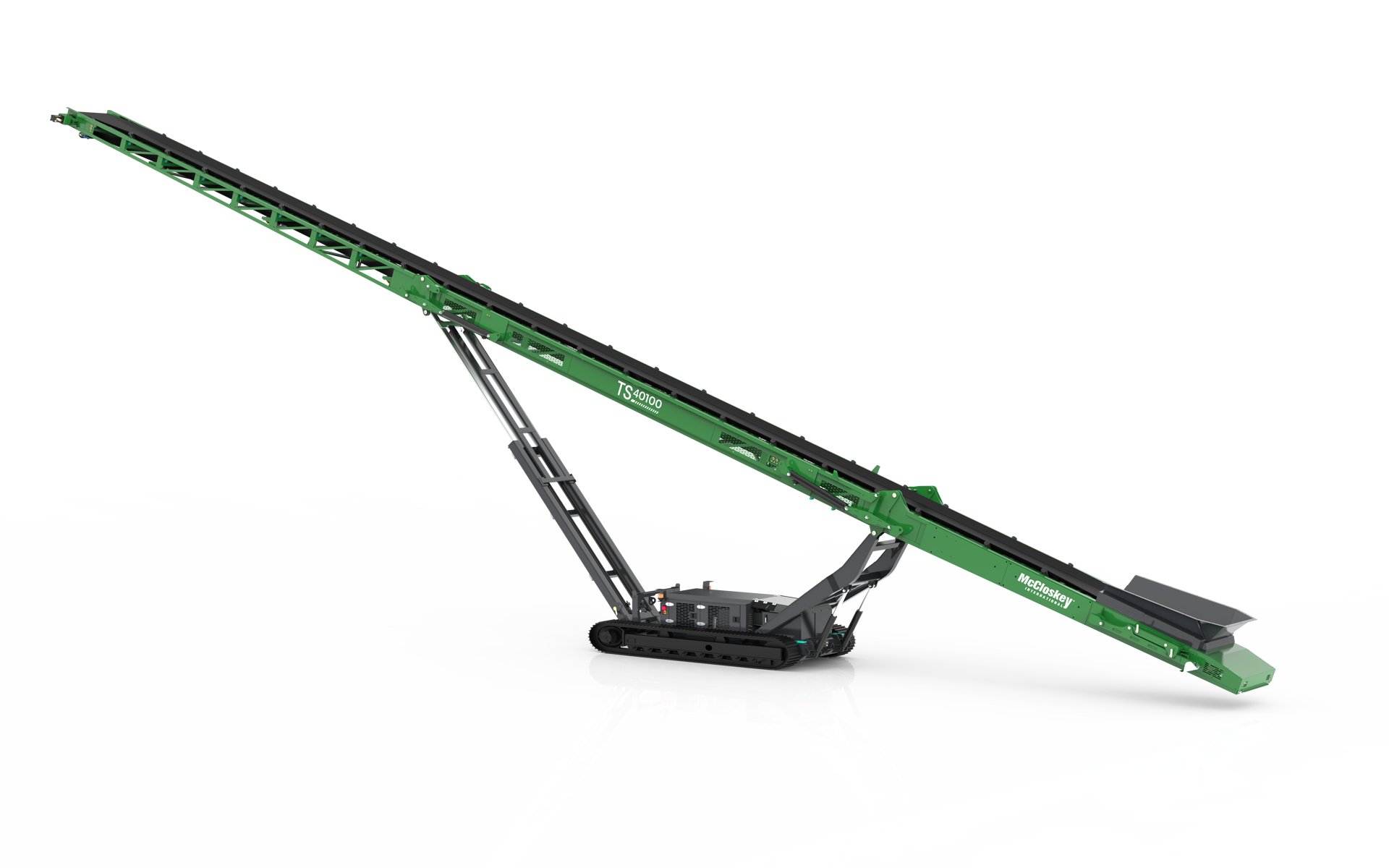

McCloskey TS40100 – 100FT Tracked Stacker

Applications and Performance

Perfect for:

- High-volume quarry and aggregate sites

- Mining and bulk material stockpiling

- Port and terminal operations

- Industrial-scale mobile crushing and screening systems

The TS40100 enhances efficiency by reducing the need for additional handling equipment, allowing for faster material transfer, reduced operational costs, and increased site safety.

Why Choose the McCloskey TS40100?

For operators requiring the highest levels of productivity and versatility, the McCloskey TS40100 is a standout solution. It combines long-reach capabilities, exceptional throughput, and intuitive controls in a mobile format that’s easy to deploy and operate — making it the ideal choice for bulk handling on a grand scale.

Operating Rate

800 TPH*

Operating Rate

800 TPH* Stockpile Height

13 metres

Stockpile Height

13 metres Conveyor Width

1000mm (40”)

Conveyor Width

1000mm (40”)  Conveyor Length

30,500mm (100’)

Conveyor Length

30,500mm (100’)

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.