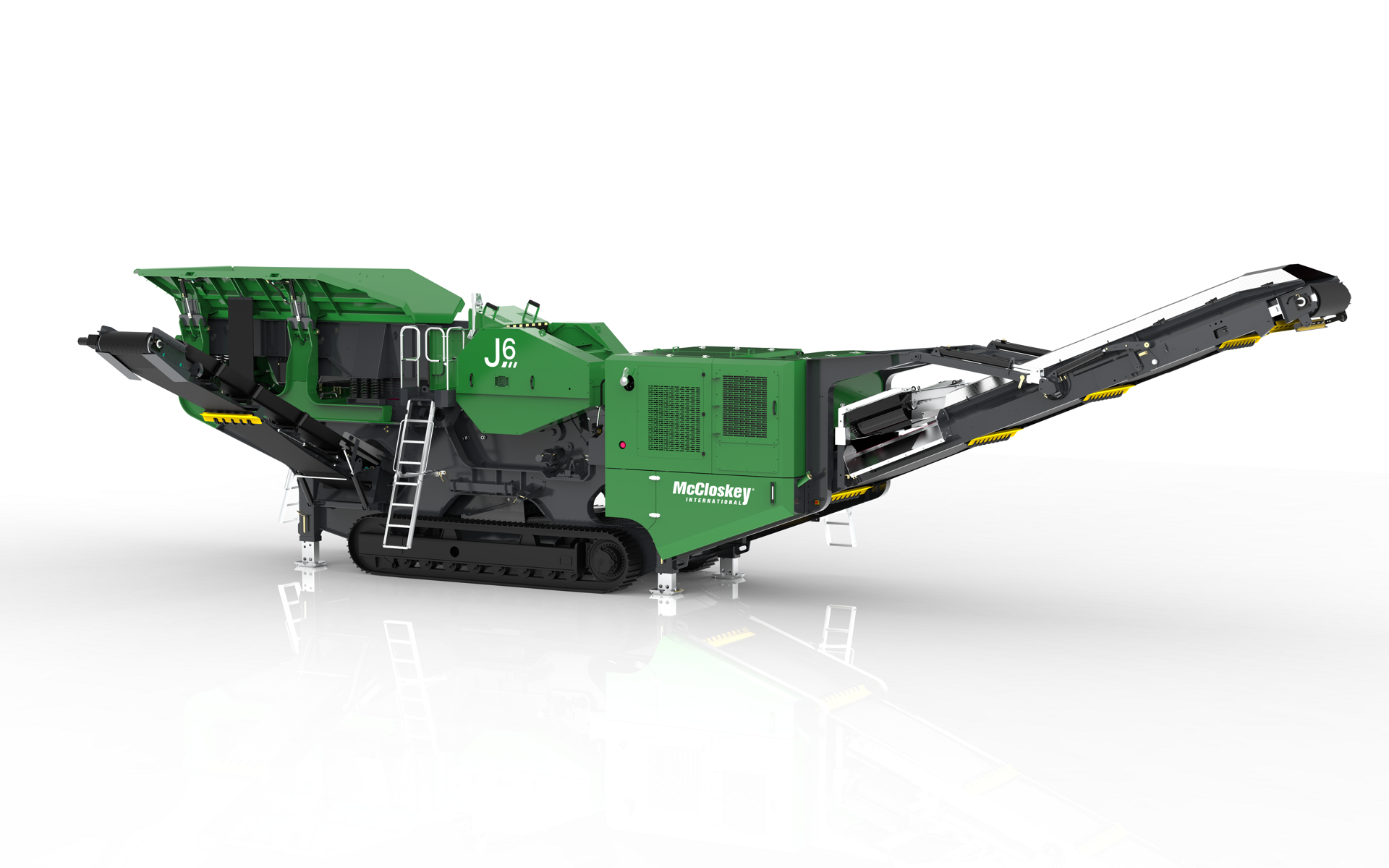

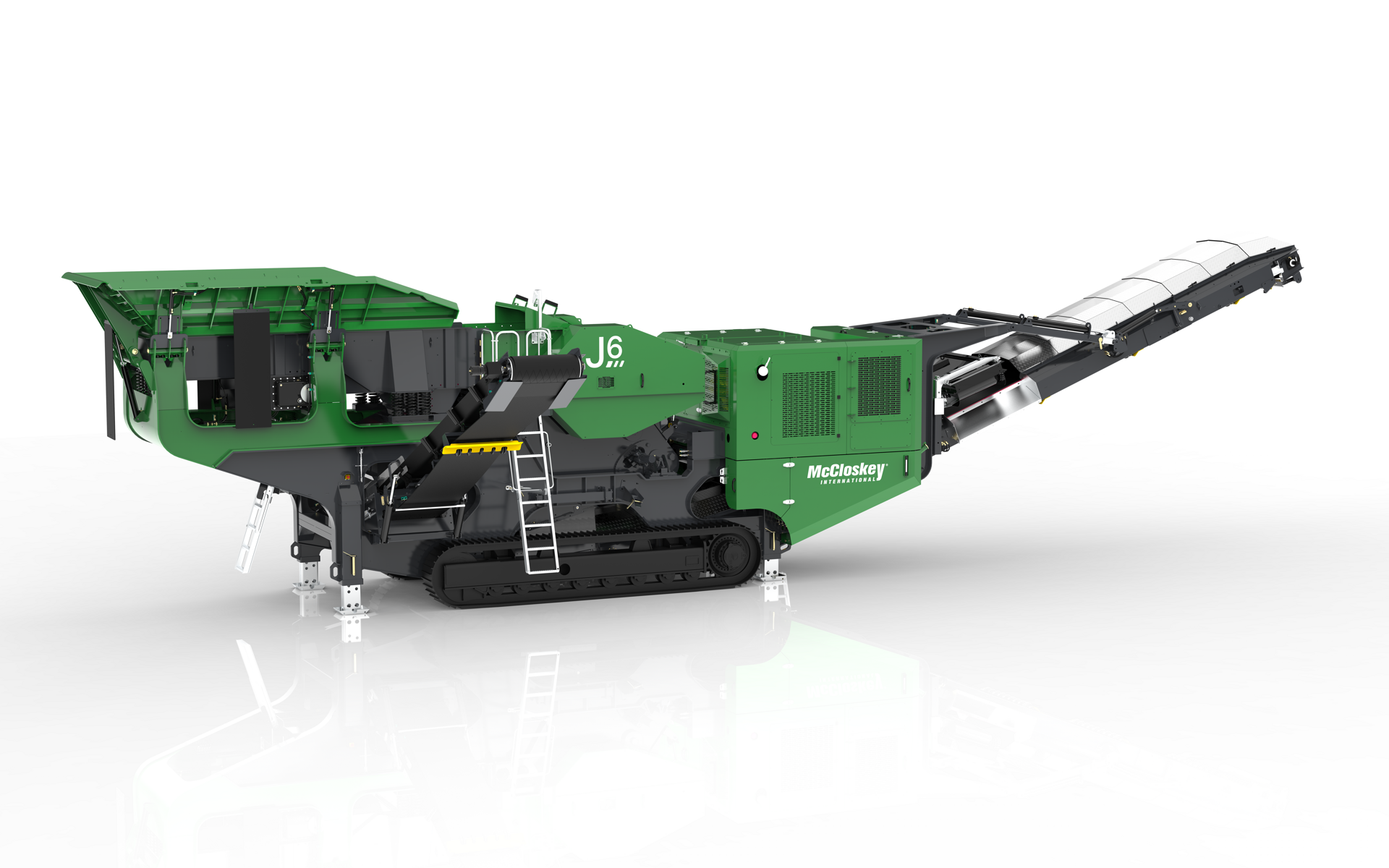

McCloskey J6 Jaw Crusher

Applications and Benefits

The J6 is ideal for:

-

High-capacity aggregate production

-

Primary crushing in hard rock quarries

-

Heavy construction and infrastructure development

-

Processing of oversize demolition material

Why Choose the McCloskey J6?

If your operation requires maximum output, durability, and minimal downtime, the McCloskey J6 delivers. It combines brute power with advanced screening and material handling features — making it the flagship model in McCloskey’s jaw crusher lineup. Designed for serious operators tackling serious workloads.

Machine Weight

70,200KG

Machine Weight

70,200KG Chamber Dims

1200mm x 864mm

Chamber Dims

1200mm x 864mm Pre Screen

Yes

Pre Screen

Yes Engine

CAT C13

Engine

CAT C13

MACHINE BENEFITS

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.

A primary crusher with superior shaping ability, the R5 Impact Crusher fills a variety of roles using just one piece of equipment. The R5’s built in pre-screen’s, post-screens and recirculation conveyor ensures maximum product quality and throughput.